Before any maintenance operation, deactivate the appliance and disconnect the mains plug from the socket.

Always take care when moving appliances, for heavy appliances it's necessary two persons to move it.

Always use safety gloves and enclosed footwear.

Please note that self-repair or nonprofessional repair can have safety consequences if not done properly

How to disassemble and assemble the bellow seal

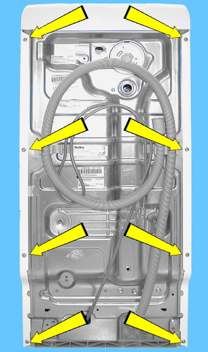

Start by removing the side panels so that you can access all various parts of the washing machine.

Unfasten the screws that fix the right or left side panel (appliance viewed from the front) to the back panel.

Move it towards the back of the washing machine

so as to allow its removal from the upper guides, marked by the arrows in the drawing.

Bellow seal

Remove the left and right side panels (see relevant chapter).

Remove the wiring from the various supports (indicated by the arrows).

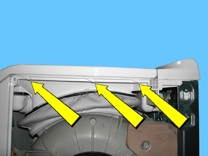

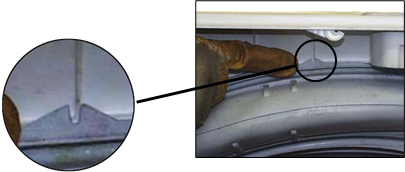

Using a screwdriver, open the clamp, taking care not to perforate the bellow seal or break the locking ring.

Remove the bellow taking care not to ruin the 2 bases.

When reassembling.

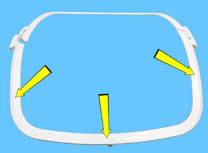

Lubricate the whole of the inlet seat into which the bellow seal is to be inserted.

Lubricate the bellow seal seat to be inserted into the inlet.

(The bottom part is not indicated by the arrows because it is hidden.)

After lubricating the two seats, the inlet seat and the bellow seal seat.

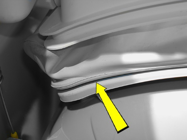

Find the position of the reference symbol on the edge of the inlet.

The position of the reference symbol on the bellow seal.

Insert the seal between the inlet and the welded tub.

Position the two references so that they correspond.

And insert the bellow seal into the loading inlet seat.

Lubricate the part of the locking ring that is to be inserted into the bellow seal

seat, to fix it tightly to the welded tub.

Lubricate the bellow seal seat indicated by the arrow.

Insert the locking ring between the bellow seal and the inlet.

Check that the bellow is inserted precisely and that the reference notches are positioned properly from both sides

Check that the locking ring is inserted perfectly in its seat around the whole perimeter.

Join the two ends of the locking ring.

Tighten with a pipe wrench (be careful not to break the ring).

Repeat the operations carried out with this locking ring with the locking ring fixing the bellow seal to the inlet.